|

Tyrone's 2004 convertible 350z

Tyrone was on his way to ride CrotchOfTheDragon.com Route 622, when on the interstate, a huge rock broke his radiator and lead to a motor failure. Luckily, he was within 10 miles of JGY. Geico sent the car here for a motor swap. We will also be doing some tasteful motor upgrades, as well.

On the lift

Getting ready to take the motor out

Driveshaft and exhaust components out

Transmission out

Previously installed clutch looking good

Motor out

Old motor

Replacement motor

Agency Power pulley kit

Greddy carbon fiber air diversion plate for radiator

Megan Racing radiator hoses

New stainless steel headers

Once we took the motor out, we found out why it moved so much... the left motor mount is broken

Trying to remove the radiator seemed different on this Z... Well, the convertibles came equipped with a 22 pound energy absorber in the front left corner of the bay...

Removing the motor mount brackets to install on the replacement motor

Replacement motor has the oil filter in the front instead of the side of the block

Upon removing the motor, we found this broken driver's side motor mount

Old motor getting stripped of usable parts

We will reuse his great shape factory clutch and flywheel

Removing the factory automatic transmission pilot bearing

3 of the flywheel to crankshaft mounting points needed to be cleaned up/re-tapped

Removing Tyrone's RWD oil pans and accessories so that we could install them onto the AWD donor motor for it to fit his car. The AWD version of the VQ motor has the starter on the driver side, where the RWD has it on the US passenger side. Also, the AWD oil pan is larger to accommodate the front axle shaft that runs through it.

Getting ready to remove the AWD oil pan from the new motor

Notice the replacement motor is much cleaner inside than the old one

Replacement motor ready for RWD oil pan

Installed RWD upper and lower oil pans with new gasket

We installed the Agency Power light weight pulleys onto his motor for added power.

We swapped over the alternator and motor mounts from his motor.

We found two melted coil packs from the overheated motor and replaced them.

We prepped the intake for the Blox Racing Plenum Spacer.

The spacer easily installs and provides cooler intake air, better throttle response, and clears the strut bar.

After installed with the included Blox longer hardware, the fitment is great.

Motor is going in. Once the motor is barely in the bay, the headers will be installed.

Motor being installed

Headers waiting to be installed

Motor is in and you can see the Agency Power pulleys

Now connecting the harness

Agency Power pulleys installed with corresponding belts

Flywheel installed

Clutch disk added

Pressure plate

Transmission

New fans

New, bigger Mizu radiator to be installed

Tyrone's fans and radiator installed, and a view of the pulleys

View of the Blox Racing spacer

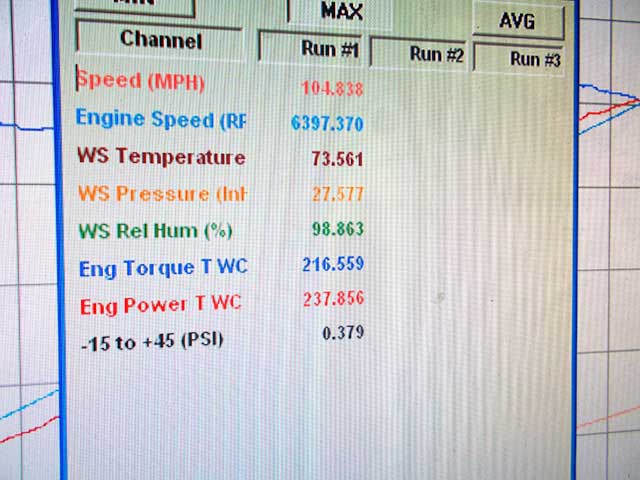

Ready for the dyno

Getting ready to dyno

UpRev engine management

Dyno work

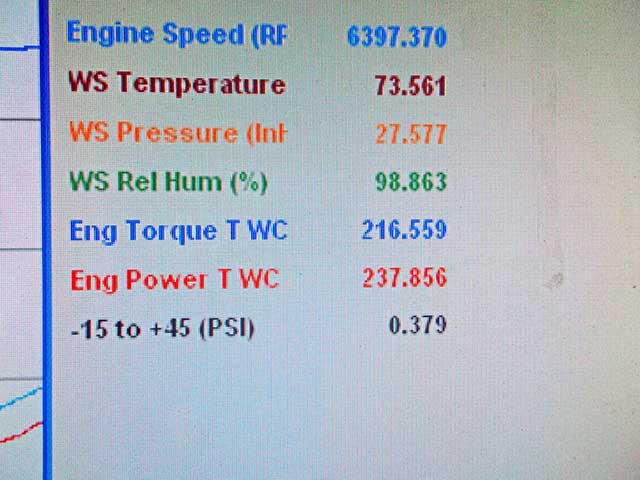

After dyno tuning with UpRev, we went from the lower 200's in both up to over 235HP and 216tq

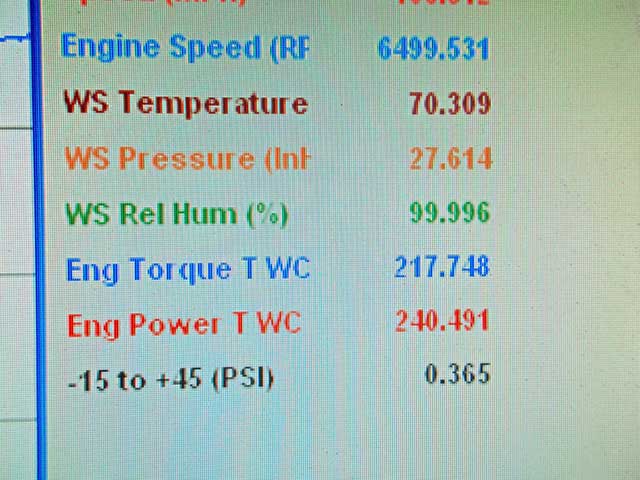

With more refining, we achieved a touch over 240HP and 217 tq

Greddy's Air Diversion Plate in carbon fiber installed

Test fitting the new wheels, 285/30/20's for the rear

Project completed

|